●Ultra-fine Cemented Carbide

●Suitable for Stainless Steel, various Steel Alloy and Steel machining

●Realize high efficiency processing

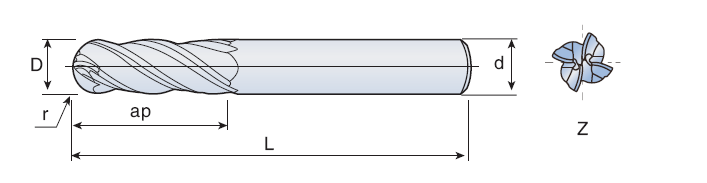

●4F, Ball End, X coating, Unequal indexing, Multiple helix

●Unique design maximizes chip removal and improves productivity in slotting and heavy profiling operations.

●Recommend Application: Rough and Semi-Finish processing for Stainless Steel

| P/N |

D

(mm)

|

ap

(mm)

|

d

(mm)

|

L

(mm)

|

F# | Tip | Coating |

| GCP435 030 F2 26 057 B X | 3 | 8 | 6 | 57 | 4 | BN | Microkevlar X |

| GCP435 040 F2 27 057 B X | 4 | 11 | 6 | 57 | 4 | BN | Microkevlar X |

| GCP435 050 F2 26 057 B X | 5 | 13 | 6 | 57 | 4 | BN | Microkevlar X |

| GCP435 060 D 21 057 B X | 6 | 13 | 6 | 57 | 4 | BN | Microkevlar X |

| GCP435 080 D 23 063 B X | 8 | 19 | 8 | 63 | 4 |

BN |

Microkevlar X |

| GCP435 100 D 22 072 B X | 10 | 22 | 10 | 72 | 4 | BN | Microkevlar X |

| GCP435 120 D 21 083 B X | 12 | 26 | 12 | 83 | 4 | BN | Microkevlar X |

| GCP435 160 D 20 092 B X | 16 | 32 | 16 | 92 | 4 | BN | Microkevlar X |

| GCP435 200 D 19 104 B X | 20 | 38 | 20 | 104 | 4 | BN | Microkevlar X |

| GCP435 250 D 15 104 B X | 25 | 38 | 25 | 104 | 4 | BN | Microkevlar X |

| GCP435 Speed and Recommendations | |||||||||||||

|

ISO GROUP |

CMG |

Type of cut |

ap*Dc |

ae*Dc |

Vc |

Parameters |

4 | 6 | 8 | 10 | 12 | 16 | 20 |

| P |

P 1-2 |

Side Milling |

1.5 | 0.5 |

152 130-168 |

RPM | 12125 | 8080 | 6060 | 5345 | 4450 | 3340 | 2670 |

| Fz | 0.008 | 0.016 | 0.027 | 0.038 | 0.047 | 0.053 | 0.065 | ||||||

| F | 395 | 520 | 665 | 820 | 835 | 710 | 695 | ||||||

|

Slotting |

1 | 1 |

112 91-135 |

RPM | 9710 | 6470 | 4850 | 3880 | 3240 | 2430 | 1783 | ||

| Fz | 0.008 | 0.016 | 0.027 | 0.038 | 0.047 | 0.053 | 0.065 | ||||||

| F | 310 | 414 | 523 | 589 | 609 | 515 | 463 | ||||||

|

P 3-4 |

Side Milling |

1 | 0.5 |

107 95-130 |

RPM | 8485 | 5655 | 4240 | 3740 | 3100 | 2330 | 1870 | |

| Fz | 0.008 | 0.016 | 0.027 | 0.038 | 0.047 | 0.053 | 0.065 | ||||||

| F | 275 | 365 | 460 | 575 | 580 | 490 | 485 | ||||||

|

Slotting |

1 | 1 |

99 84-114 |

RPM | 7880 | 5250 | 3940 | 3150 | 2630 | 1970 | 1576 | ||

| Fz | 0.008 | 0.016 | 0.027 | 0.038 | 0.047 | 0.053 | 0.065 | ||||||

| F | 252 | 336 | 425 | 478 | 494 | 417 | 409 | ||||||

|

P 5-6 |

Side Milling |

1 | 0.5 |

70 60-81 |

RPM | 5090 | 3395 | 2545 | 2240 | 1860 | 1400 | 1120 | |

| Fz | 0.006 | 0.011 | 0.019 | 0.027 | 0.032 | 0.037 | 0.045 | ||||||

| F | 115 | 150 | 190 | 240 | 240 | 205 | 200 | ||||||

|

Slotting |

1 | 1 |

61 55-67 |

RPM | 4850 | 3240 | 2430 | 1940 | 1620 | 1210 | 971 | ||

| Fz | 0.006 | 0.011 | 0.019 | 0.027 | 0.032 | 0.037 | 0.045 | ||||||

| F | 116 | 142 | 184 | 209 | 207 | 179 | 174 | ||||||

| K |

K 12-13 |

Side Milling |

1 | 0.5 |

130 110-150 |

RPM | 10335 | 6890 | 5161 | 4558 | 3775 | 2842 | 2279 |

|

Fz |

0.01 | 0.02 | 0.034 | 0.048 | 0.058 | 0.065 | 0.081 | ||||||

| F | 413 | 551 | 702 | 875 | 875 | 738 | 738 | ||||||

|

Slotting |

1 | 1 |

112 91-135 |

RPM | 8910 | 5940 | 4455 | 3930 | 3255 | 2450 | 1965 | ||

| Fz | 0.01 | 0.02 | 0.034 | 0.048 | 0.058 | 0.065 | 0.081 | ||||||

| F | 360 | 480 | 600 | 755 | 760 | 640 | 635 | ||||||

| M |

M 8-9 |

Side Milling |

1.5 | 0.5 |

105 84-126 |

RPM | 8400 | 5570 | 4178 | 3342 | 2785 | 2089 | 1674 |

| Fz | 0.008 | 0.025 | 0.034 | 0.042 | 0.048 | 0.062 | 0.071 | ||||||

| F | 268 | 550 | 572 | 559 | 529 | 516 | 476 | ||||||

|

Slotting |

1 | 1 |

85 68-102 |

RPM | 6767 | 4509 | 3382 | 2706 | 2255 | 1691 | 1353 | ||

| Fz | 0.008 | 0.025 | 0.034 | 0.042 | 0.048 | 0.062 | 0.071 | ||||||

| F | 216 | 446 | 463 | 452 | 428 | 418 | 386 | ||||||

| M10 |

Side Milling |

1 | 0.4 |

155 124-186 |

RPM | 11740 | 8223 | 6167 | 4934 | 4112 | 3084 | 2467 | |

| Fz | 0.006 | 0.034 | 0.046 | 0.057 | 0.067 | 0.086 | 0.095 | ||||||

| F | 281 | 1125 | 1125 | 1125 | 1094 | 1055 | 937 | ||||||

|

Slotting |

1 | 1 |

125 100-150 |

RPM | 9950 | 6631 | 4974 | 3979 | 3316 | 2487 | 1989 | ||

| Fz | 0.006 | 0.034 | 0.046 | 0.057 | 0.067 | 0.081 | 0.095 | ||||||

| F | 238 | 907 | 907 | 907 | 882 | 803 | 756 | ||||||

| M11 |

Side Milling |

0.6 | 0.3 |

44 35-53 |

RPM | 3503 | 2334 | 1751 | 1401 | 1167 | 875 | 700 | |

| Fz | 0.008 | 0.016 | 0.021 | 0.027 | 0.032 | 0.04 | 0.046 | ||||||

| F | 112 | 151 | 146 | 149 | 151 | 140 | 128 | ||||||

|

Slotting |

0.4 | 1 |

36 29-43 |

RPM | 2866 | 1910 | 1432 | 1146 | 955 | 716 | 573 | ||

| Fz | 0.008 | 0.016 | 0.021 | 0.027 | 0.032 | 0.04 | 0.046 | ||||||

| F | 92 | 123 | 120 | 122 | 123 | 114 | 105 | ||||||

| S | S22 |

Side Milling |

1 | 0.4 |

70 56-84 |

RPM | 5573 | 3714 | 2785 | 2228 | 1857 | 1393 | 1114 |

| Fz | 0.007 | 0.016 | 0.025 | 0.042 | 0.05 | 0.055 | 0.068 | ||||||

| F | 156 | 237 | 278 | 374 | 371 | 306 | 303 | ||||||

|

Slotting |

1 | 1 |

55 44-66 |

RPM | 4378 | 2918 | 2188 | 1751 | 1459 | 1094 | 875 | ||

| Fz | 0.007 | 0.016 | 0.025 | 0.042 | 0.05 | 0.055 | 0.068 | ||||||

| F | 122 | 186 | 218 | 294 | 291 | 240 | 238 | ||||||

|

S 19-21 |

Side Milling |

0.6 | 0.3 |

32 26-38 |

RPM | 2547 | 1698 | 1273 | 1019 | 849 | 637 | 509 | |

| Fz | 0.005 | 0.012 | 0.019 | 0.032 | 0.038 | 0.048 | 0.055 | ||||||

| F | 51 | 81 | 96 | 130 | 129 | 122 | 112 | ||||||

|

Slotting |

0.4 | 1 |

25 20-30 |

RPM | 1990 | 1326 | 995 | 796 | 663 | 497 | 398 | ||

| Fz | 0.005 | 0.012 | 0.019 | 0.032 | 0.038 | 0.048 | 0.055 | ||||||

| F | 39 | 63 | 75 | 101 | 100 | 95 | 87 | ||||||

Machine

Machine: TMV-1100A

Power(KW)

11

Spindle speed

8000

Holder

BT40

Collet

ER32

Fixture

Precision vice

Processing

Side Milling

Workpiece

Name

Ti Alloy Structure

P/N

Material

TC15 (Ti6.5Al1Mo1V2Zr)

Heat treatment

□ Yes

Spec.

Hardness: HRC_27_

Discription

4F 8mm Ball End

Brand

Couloir Cutter

P/N

GCP435080D23063BX

Flute#/Coating

4F,R4mm,Microkevlar X

Spindle Speed(RPM)

4000rev/min

Depth of Cut(ap)

0.5mm

Width of Cut(ae)

0.5mm

Cutting speed(Vc)

100m/min

Feed per tooth(CTP)

0.0625mm

Feed (F)

1000mm/min

Cutter reach

27mm

Cooling

Emulsion

Time/pce

85min

Tool life

2pcs

Conclusion

GCP435080D23063X completed 2pcs in 170min. Tool wear:0.08mm

XIAN COULOIR CUTTER CO., LTD

XIAN COULOIR CUTTER CO., LTD

Adress:4FL, BINTIAN MANSION, YONGLE INDUSTRIAL PARK, JINGHE NEW CITY OF XIXIAN NEW AREA, SHAANXI PROVINCE, CHINA. 713702

TEL:86-29-38952897/15091858296

FAX:86-29-38952897

ICP Record Number:Shaanxi ICP No. 19008760-1