●Premium grade carbide

●Unequal indexing and multiple helix design effectively minimize chattering

●4F, Square end, L coating, Rougher

●Recommend Application: Suitable for difficult-to-machining materials or medium and low speed operation in poor working condition

| P/N |

D

(mm)

|

ap

(mm)

|

d

(mm)

|

L

(mm)

|

F# | Tip | Coating |

| S435 030 F1 30 050 B L | 3 | 9 | 4 | 50 | 4 | BN | Microkevlar L |

| S435 035 F1 30 050 B L | 3.5 | 10 | 4 | 50 | 4 | BN | Microkevlar L |

| S435 040 D 30 050 B L | 4 | 12 | 4 | 50 | 4 | BN | Microkevlar L |

| S435 045 F2 30 050 B L | 4.5 | 13 | 6 | 50 | 4 | BN | Microkevlar L |

| S435 050 F2 30 050 B L | 5 | 15 | 6 | 50 | 4 | BN | Microkevlar L |

| S435 055 F2 30 050 B L | 5.5 | 16 | 6 | 50 | 4 | BN | Microkevlar L |

| S435 060 D 30 050 B L | 6 | 18 | 6 | 50 | 4 | BN | Microkevlar L |

| S435 065 F3 30 060 B L | 6.5 | 20 | 8 | 60 | 4 | BN | Microkevlar L |

| S435 070 F3 30 060 B L | 7 | 21 | 8 | 60 | 4 | BN | Microkevlar L |

| S435 075 F3 30 060 B L | 7.5 | 22 | 8 | 60 | 4 | BN | Microkevlar L |

| S435 080 D 30 060 B L | 8 | 24 | 8 | 60 | 4 | BN | Microkevlar L |

| S435 085 F4 30 075 B L | 8.5 | 25 | 10 | 75 | 4 | BN | Microkevlar L |

| S435 090 F4 30 075 B L | 9 | 27 | 10 | 75 | 4 | BN | Microkevlar L |

| S435 095 F4 30 075 B L | 9.5 | 28 | 10 | 75 | 4 | BN | Microkevlar L |

| S435 100 D 30 075 B L | 10 | 30 | 10 | 75 | 4 | BN | Microkevlar L |

| S435 105 F5 30 075 B L | 10.5 | 31 | 12 | 75 | 4 | BN | Microkevlar L |

| S435 110 F5 30 075 B L | 11 | 33 | 12 | 75 | 4 | BN | Microkevlar L |

| S435 120 D 30 075 B L | 12 | 36 | 12 | 75 | 4 | BN | Microkevlar L |

| S435 130 F6 30 100 B L | 13 | 39 | 14 | 100 | 4 | BN | Microkevlar L |

| S435 140 F6 30 100 B L | 14 | 42 | 14 | 100 | 4 | BN | Microkevlar L |

| S435 150 F7 30 100 B L | 15 | 45 | 16 | 100 | 4 | BN | Microkevlar L |

| S435 160 D 30 100 B L | 16 | 48 | 16 | 100 | 4 | BN | Microkevlar L |

| S435 200 D 25 100 B L | 20 | 50 | 20 | 100 | 4 | BN | Microkevlar L |

ISO

GROUP

P

1-2

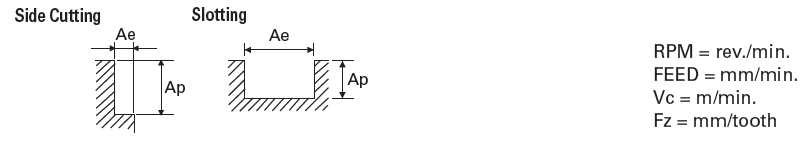

Side Milling

Slotting

P

3-4

Side Milling

Slotting

P

5-6

Side Milling

Slotting

M

8-9

Side Milling

Slotting

M

10-11

Side Milling

Slotting

K

12-13

Side Milling

Slotting

K

14-15

Side Milling

Slotting

Side Milling

Slotting

Side Milling

Slotting

Side Milling

Slotting

Side Milling

Slotting

S435 Speed and Recommendations

CMG

Type of cut

ap*Dc

ae*Dc

Vc

Parameters

6

10

12

16

20

P

1

3

122

104-140

RPM

6470

3880

3240

2430

1940

Fz

0.027

0.045

0.054

0.072

0.09

F

699

698

700

700

698

0.5

1

122

104-140

RPM

6470

3880

3240

2430

1940

Fz

0.022

0.036

0.043

0.058

0.072

F

559

559

560

560

559

1

3

61

43-79

RPM

3240

1940

1620

1210

970

Fz

0.017

0.028

0.034

0.045

0.056

F

218

217

218

217

217

0.4

1

61

43-79

RPM

3240

1940

1620

1210

970

Fz

0.013

0.022

0.027

0.036

0.045

F

174

174

174

173

174

1

2

30

12-49

RPM

1590

950

800

600

480

Fz

0.007

0.014

0.024

0.029

0.038

F

92

91

92

92

92

0.3

1

30

12-49

RPM

1590

950

800

600

480

Fz

0.012

0.019

0.023

0.031

0.038

F

73

73

74

74

74

M

0.5

0.3

98

88-107

RPM

5200

3120

2600

1950

1560

Fz

0.013

0.022

0.026

0.035

0.044

F

275

275

275

275

275

0.5

1

98

88-107

RPM

5200

3120

2600

1950

1560

Fz

0.011

0.018

0.021

0.028

0.035

F

220

220

220

220

220

0.3

0.2

76

67-85

RPM

4030

2420

2020

1510

1210

Fz

0.012

0.02

0.024

0.032

0.04

F

193

194

194

193

194

0.4

1

76

67-85

RPM

4030

2420

2020

1510

1210

Fz

0.010

0.016

0.0196

0.026

0.032

F

155

155

155

155

155

K

1

0.5

82

64-101

RPM

4350

2610

2180

1630

1310

Fz

0.035

0.058

0.07

0.093

0.116

F

606

606

607

605

608

0.5

1

82

64-101

RPM

4350

2610

2180

1630

1310

Fz

0.028

0.046

0.056

0.074

0.093

F

484

484

484

484

484

0.5

0.3

44

26-62

RPM

2330

1400

1170

880

700

Fz

0.020

0.034

0.041

0.054

0.068

F

190

190

191

191

190

0.3

1

44

26-62

RPM

2330

1400

1170

880

700

F

0.016

0.027

0.033

0.044

0.054

F

152

152

152

152

152

S

S 19

0.2

1

37

27-46

RPM

1960

1180

980

740

590

Fz

0.014

0.024

0.029

0.038

0.048

F

113

113

113

114

113

0.2

1

21

12-30

RPM

1110

670

560

420

330

Fz

0.018

0.030

0.036

0.048

0.060

F

80

80

81

81

79

S 20

0.2

1

37

27-46

RPM

1960

1180

980

740

590

Fz

0.014

0.024

0.029

0.038

0.048

F

113

113

113

114

113

0.2

1

21

12-30

RPM

1110

670

560

420

330

Fz

0.018

0.030

0.036

0.048

0.060

F

80

80

81

81

79

S

21

0.2

1

37

27-46

RPM

1960

1180

980

740

590

Fz

0.014

0.024

0.029

0.038

0.048

F

113

113

113

114

113

0.2

1

21

12-30

RPM

1110

670

560

420

330

Fz

0.018

0.030

0.036

0.048

0.060

F

80

80

81

81

79

S 22

0.3

0.2

24

6-43

RPM

1270

760

640

480

380

Fz

0.013

0.022

0.027

0.036

0.045

F

68

68

69

69

68

0.2

1

34

16-52

RPM

1800

1080

900

680

540

Fz

0.017

0.028

0.034

0.045

0.056

F

121

121

121

122

121

| Machine | Machine: Feeler VFP40A | ||||

| Power(KW) | 11 | Spindle speed | 8000 | ||

| Holder | BT40-ER32 | Typer | ER collet | ||

| Fixture | Fourth Axis + Centre | Processing | Side milling | ||

| Workpiece | Name | Aero-engine blade | P/N | ||

| Material | GH4169 | Heat treatment | □ Yes | ||

| Spec. | Hardness: HRC_35_ | ||||

| Discription | 4F 16MM BALL END | 4F 16MM BALL END | |||

| Brand | Couloir Cutter | Competitor | |||

| P/N | S435160D30100BL | 16*50*100L | |||

| Flute#/Coating | 4F,Microkevlar L | 4F,ALTIN | |||

| Spindle Speed(RPM) | 585rev/min | 600rev/min | |||

| Depth of Cut(ap) | 1-3mm | 1-3mm | |||

| Width of Cut(ae) | 0.8mm | 0.8mm | |||

| Cutting speed(Vc) | 30m/min | 30m/min | |||

| Feed per tooth(CTP) | 0.17mm | 0.15mm | |||

| Feed (F) | 400mm/min | 360mm/min | |||

| Cutter reach | 55mm | 27mm | |||

| Cooling | Emulsion | Emulsion | |||

| Time/pcs | 37min | 40min | |||

| Tool life | 5pcs | Chipped at the 4th part | |||

XIAN COULOIR CUTTER CO., LTD

XIAN COULOIR CUTTER CO., LTD

Adress:4FL, BINTIAN MANSION, YONGLE INDUSTRIAL PARK, JINGHE NEW CITY OF XIXIAN NEW AREA, SHAANXI PROVINCE, CHINA. 713702

TEL:86-29-38952897/15091858296

FAX:86-29-38952897

ICP Record Number:Shaanxi ICP No. 19008760-1