●Ultra-fine Cemented Carbide

●Suitable for HIGH HARDNESS Mold & Die material, HRC68

●2F, Ball end, P coating, High hardness

●Super fine grinding cutting edge, multilayer nanoscale high hardness coating. Working hardness reach to HRC68.Flexible choose on tip and flute according to your need.

●Recommend Application: MOULD INDUSTRY.

| P/N |

D

(mm)

|

ap

(mm)

|

d

(mm)

|

L

(mm)

|

F# | Tip | Coating |

| HSU235 010 F1 20 050 B P | 1 | 2 | 4 | 50 | 2 | BN | Microkevlar P |

| HSU235 015 F1 20 050 B P | 1.5 | 3 | 4 | 50 | 2 |

BN |

Microkevlar P |

| HSU235 020 F1 20 050 B P | 2 | 4 | 4 | 50 | 2 |

BN |

Microkevlar P |

| HSU235 025 F1 20 050 B P | 2.5 | 5 | 4 | 50 | 2 |

BN |

Microkevlar P |

| HSU235 030 F1 20 050 B P | 3 | 6 | 4 | 50 | 2 |

BN |

Microkevlar P |

| HSU235 040 D 20 050 B P | 4 | 8 | 4 | 50 | 2 |

BN |

Microkevlar P |

| HSU235 050 F2 20 050 B P | 5 | 10 | 6 | 50 | 2 |

BN |

Microkevlar P |

| HSU235 055 F2 21 050 B P | 5.5 | 12 | 6 | 50 | 2 |

BN |

Microkevlar P |

| HSU235 060 D 20 050 B P | 6 | 12 | 6 | 50 | 2 |

BN |

Microkevlar P |

| HSU235 080 D 20 060 B P | 8 | 16 | 8 | 60 | 2 |

BN |

Microkevlar P |

| HSU235 090 F4 20 075 B P | 9 | 18 | 10 | 75 | 2 |

BN |

Microkevlar P |

| HSU235 100 D 20 075 B P | 10 | 20 | 10 | 75 | 2 |

BN |

Microkevlar P |

| HSU235 120 D 20 075 B P | 12 | 24 | 12 | 75 | 2 |

BN |

Microkevlar P |

| HSU235 Speed and Recommendations | |||||||||||||||

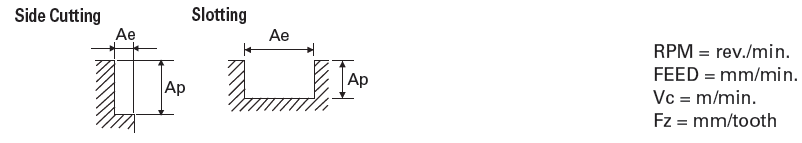

| ISO GROUP | CMG |

Type of cut |

ap*Dc |

ae*Dc |

Vc |

Parameters |

2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 16 |

| P | P6 |

Side Milling |

0.1 | 0.1 |

80

60-100

|

RPM | 12738 | 8492 | 6369 | 5095 | 4246 | 3184 | 2547 | 2123 | 1592 |

| Fz | 0.008 | 0.01 | 0.015 | 0.02 | 0.025 | 0.03 | 0.04 | 0.05 | 0.06 | ||||||

| F | 203 | 169 | 191 | 203 | 212 | 191 | 203 | 212 | 191 | ||||||

| H | H7 |

Side Milling |

0.05 | 0.1 |

50

35-65

|

RPM | 7961 | 5307 | 3980 | 3184 | 2653 | 1990 | 1592 | 1326 | 995 |

| Fz | 0.003 | 0.005 | 0.007 | 0.008 | 0.01 | 0.012 | 0.016 | 0.02 | 0.024 | ||||||

| F | 48 | 53 | 56 | 51 | 53 | 48 | 51 | 53 | 48 | ||||||

Machine

Machine: HISION BF20

Power(KW)

43

Spindle speed

24000

Holder

HSK100

collet

hydraulic

Fixture

Tailor-made

Working way

Forming Milling

Workpiece

Name

Car Mold

P/N

Material

H13/XPM

Heat treatment

□ yes

Spec.

HRC: HRC_45-55_

Discription

8mm ball end mill

8mm ball end mill

Brand

Couloir Cutter

Couloir Cutter

P/N

HSU235080D20060BP

HSU235080D20060BP

Flute#/Coating

2F,Microkevlar P

2F,Microkevlar P

Spindle Speed(RPM)

16000rev/min

10000rev/min

Depth of Cut(ap)

0.06mm

0.08mm

Width of Cut(ae)

Variable

Variable

Cutting speed(Vc)

400m/min

250m/min

Feed per tooth(CTP)

0.156mm

0.115mm

Feed (F)

5000mm/min

2300mm/min

Cutter reach

30mm

30mm

Cooling

oil

emulsion

Surface finish

Ra1.2

Ra1.2

Tool life

8Hr, tool wear 0.04mm

9Hr, tool wear 0.06mm

XIAN COULOIR CUTTER CO., LTD

XIAN COULOIR CUTTER CO., LTD

Adress:4FL, BINTIAN MANSION, YONGLE INDUSTRIAL PARK, JINGHE NEW CITY OF XIXIAN NEW AREA, SHAANXI PROVINCE, CHINA. 713702

TEL:86-29-38952897/15091858296

FAX:86-29-38952897

ICP Record Number:Shaanxi ICP No. 19008760-1