●Ultra-fine Cemented Carbide

●Suitable for Finish and Cycloidal milling of all material besides high hardness material

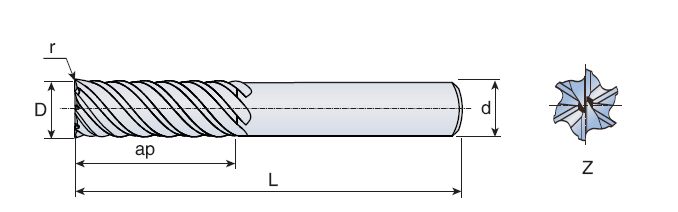

●6F, Square end, X coating, Multiple helix

●Realize high efficiency processing in the way of HIGH FEED. Special design maximizes chip removal and improves productivity. Good surface finish.

P/N

Flute Dia.

(mm)

Flute Length

(mm)

Shank Dia.

(mm)

Overall Length

(mm)

F#

Tip

Coating

GCP635 060 D 21 057 R050 X

6

13

6

57

6

R0.5

Microkevlar X

GCP635 060 D 21 057 R100 X

6

13

6

57

6

R1

Microkevlar X

GCP635 080 D 23 063 R050 X

8

19

8

63

6

R0.5

Microkevlar X

GCP635 080 D 23 063 R100 X

8

19

8

63

6

R1

Microkevlar X

GCP635 100 D 22 072 R050 X

10

22

10

72

6

R0.5

Microkevlar X

GCP635 100 D 22 072 R100 X

10

22

10

72

6

R1

Microkevlar X

GCP635 100 D 22 072 R150 X

10

22

10

72

6

R1.5

Microkevlar X

GCP635 100 D 22 072 R200 X

10

22

10

72

6

R2

Microkevlar X

GCP635 120 D 21 083 R050 X

12

26

12

83

6

R0.5

Microkevlar X

GCP635 120 D 21 083 R100 X

12

26

12

83

6

R1

Microkevlar X

GCP635 120 D 21 083 R150 X

12

26

12

83

6

R1.5

Microkevlar X

GCP635 120 D 21 083 R200 X

12

26

12

83

6

R2

Microkevlar X

GCP635 120 D 21 083 R300 X

12

26

12

83

6

R3

Microkevlar X

GCP635 160 D 20 092 R100 X

16

32

16

92

6

R1

Microkevlar X

GCP635 160 D 20 092 R150 X

16

32

16

92

6

R1.5

Microkevlar X

GCP635 160 D 20 092 R200 X

16

32

16

92

6

R2

Microkevlar X

GCP635 160 D 20 092 R300 X

16

32

16

92

6

R3

Microkevlar X

GCP635 200 D 19 104 R100 X

20

38

20

104

6

R1

Microkevlar X

GCP635 200 D 19 104 R150 X

20

38

20

104

6

R1.5

Microkevlar X

GCP635 200 D 19 104 R200 X

20

38

20

104

6

R2

Microkevlar X

GCP635 200 D 19 104 R300 X

20

38

20

104

6

R3

Microkevlar X

GCP635 250 D 17 104 R100 X

25

44

25

104

6

R1

Microkevlar X

GCP635 250 D 17 104 R150 X

25

44

25

104

6

R1.5

Microkevlar X

GCP635 250 D 17 104 R200 X

25

44

25

104

6

R2

Microkevlar X

GCP635 250 D 17 104 R300 X

25

44

25

104

6

R3

Microkevlar X

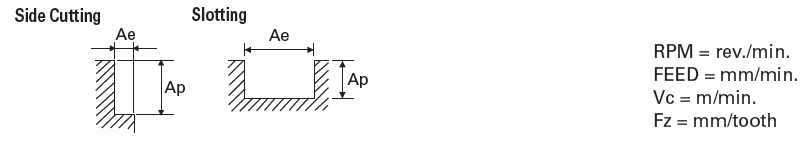

| GCP635R Speed and Recommendations | |||||||||||||

|

ISO GROUP |

CMG |

Type of cut |

ap*Dc |

ae*Dc |

Vc |

Parameters |

6 | 8 | 10 | 12 | 16 | 20 | 25 |

| P |

P

1-2

|

Side Milling |

2 | 0.05 |

300 210-390 |

RPM | 15890 | 11920 | 9540 | 7950 | 5960 | 4470 | 3820 |

| Fz | 0.068 | 0.116 | 0.144 | 0.173 | 0.202 | 0.225 | 0.232 | ||||||

| F | 6440 | 8270 | 8253 | 8245 | 7210 | 6440 | 5315 | ||||||

|

P

3-4

|

Side Milling |

2 | 0.05 |

203 142-264 |

RPM | 10770 | 8080 | 6460 | 5380 | 4040 | 3230 | 2590 | |

| Fz | 0.050 | 0.085 | 0.106 | 0.128 | 0.148 | 0.167 | 0.174 | ||||||

| F | 3240 | 4115 | 4125 | 4130 | 3620 | 3235 | 2700 | ||||||

|

P

5-6

|

Side Milling |

2 | 0.05 |

100 70-130 |

RPM | 5300 | 3970 | 3180 | 2650 | 1990 | 1590 | 1270 | |

| Fz | 0.041 | 0.071 | 0.088 | 0.105 | 0.123 | 0.137 | 0.144 | ||||||

| F | 1300 | 1685 | 1680 | 1675 | 1465 | 1310 | 1100 | ||||||

| M |

M

8-9

|

Side Milling |

2 | 0.05 |

147 103-191 |

RPM | 7820 | 5860 | 4690 | 3910 | 2930 | 2340 | 1870 |

| Fz | 0.041 | 0.071 | 0.088 | 0.105 | 0.123 | 0.137 | 0.143 | ||||||

| F | 1920 | 2485 | 2475 | 2470 | 2160 | 1930 | 1610 | ||||||

| M10 |

Side Milling |

2 | 0.05 |

213 149-277 |

RPM | 11290 | 8470 | 6770 | 5640 | 4230 | 3390 | 2710 | |

| Fz | 0.049 | 0.084 | 0.104 | 0.125 | 0.146 | 0.162 | 0.168 | ||||||

| F | 3330 | 4265 | 4240 | 4230 | 3715 | 3305 | 2730 | ||||||

| M11 |

Side Milling |

2 | 0.05 |

134 93.8-175 |

RPM | 7120 | 5340 | 4270 | 3560 | 2670 | 2140 | 1710 | |

| Fz | 0.041 | 0.071 | 0.088 | 0.105 | 0.123 | 0.137 | 0.142 | ||||||

| F | 1750 | 2265 | 2255 | 2250 | 1970 | 1760 | 1460 | ||||||

| S | S22 |

Side Milling |

2 | 0.05 |

116 35-21 |

RPM | 6170 | 4620 | 3700 | 3080 | 2310 | 18550 | 1480 |

|

Fz |

0.033 | 0.055 | 0.070 | 0.083 | 0.097 | 0.113 | 0.117 | ||||||

| F | 1210 | 1535 | 1545 | 1535 | 1350 | 1250 | 1040 | ||||||

|

S

19-21

|

Side Milling |

2 | 0.05 |

33 23-43 |

RPM | 1740 | 1300 | 1040 | 870 | 850 | 520 | 420 | |

| Fz | 0.033 | 0.055 | 0.070 | 0.082 | 0.097 | 0.112 | 0.115 | ||||||

| F | 340 | 430 | 435 | 430 | 380 | 350 | 290 | ||||||

| Machine | Machine: HERMLE C40 U | ||||

| Power(KW) | 29 | Spindle speed | 12000 | ||

| Holder | HSK63 | Holder Type | Hydraulic chuck | ||

| Fixture | Tailor-made | Processing | Cycloid milling | ||

| Workpiece | Name | Engine Blisk | P/N | ||

| Material | Ti6Al4V | Heat treatment | □ Yes | ||

| Spec. | Hardness: HRC_30_ | ||||

| Discription | 25mm 6F R1.5 | ||||

| Brand | Couloir Cutter |

|

|||

| P/N | GCP635250D40170R150X | ||||

| Flute#/Coating | 6F,R1.5,Microkevlar X | ||||

| Spindle Speed(RPM) | 1150rev/min | ||||

| Depth of Cut(ap) | 75mm | ||||

| Width of Cut(ae) | 1.5mm | ||||

| Cutting speed(Vc) | 90m/min | ||||

| Feed per tooth(CTP) | 0.15mm | ||||

| Feed (F) | 1035mm/min | ||||

| Cutter reach | 120mm | ||||

| Cooling | emulsion | ||||

| Time/pcs | 138min | ||||

| Tool life | 1 pce | ||||

| Conclusion | Save 67mins aginst previous tool | ||||

XIAN COULOIR CUTTER CO., LTD

XIAN COULOIR CUTTER CO., LTD

Adress:4FL, BINTIAN MANSION, YONGLE INDUSTRIAL PARK, JINGHE NEW CITY OF XIXIAN NEW AREA, SHAANXI PROVINCE, CHINA. 713702

TEL:86-29-38952897/15091858296

FAX:86-29-38952897

ICP Record Number:Shaanxi ICP No. 19008760-1