整体硬质合金

适用于不锈钢,合金钢和铸铁

通用型

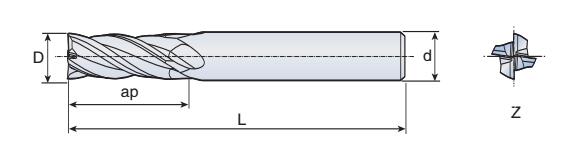

4刃, 尖角, D涂层, 通用

通用性高,一种大螺旋角铣刀,能应对小功率

机床 工况较差的加工,加强的刃口支撑强度

适合一般机械加工

| 规格 |

刃径 (mm) |

刃长 (mm) |

柄径 (mm) |

总长 (mm) |

刃数 | 刀尖 | 涂层 |

| C445 030 F1 40 050 S D | 3 | 12 | 4 | 50 | 4 | 尖角 | Microkevlar D |

| C445 040 D 50 060 S D | 4 | 20 | 4 | 60 | 4 | 尖角 | Microkevlar D |

| C445 040 F2 50 075 S D | 4 | 20 | 6 | 75 | 4 | 尖角 | Microkevlar D |

| C445 050 F2 40 075 S D | 5 | 20 | 6 | 75 | 4 | 尖角 | Microkevlar D |

| C445 050 F2 60 075 S D | 5 | 30 | 6 | 75 | 4 | 尖角 | Microkevlar D |

| C445 060 D 26 075 S D | 6 | 16 | 6 | 75 | 4 | 尖角 | Microkevlar D |

| C445 060 D 50 075 S D | 6 | 30 | 6 | 75 | 4 | 尖角 | Microkevlar D |

| C445 080 D 25 075 S D | 8 | 20 | 8 | 75 | 4 | 尖角 | Microkevlar D |

| C445 080 D 50 090 S D | 8 | 40 | 8 | 90 | 4 | 尖角 | Microkevlar D |

| C445 100 D 25 100 S D | 10 | 25 | 10 | 100 | 4 | 尖角 | Microkevlar D |

| C445 100 D 50 100 S D | 10 | 50 | 10 | 100 | 4 | 尖角 | Microkevlar D |

| C445 120 D 40 100 S D | 12 | 50 | 12 | 100 | 4 | 尖角 | Microkevlar D |

| C445 160 D 35 125 S D | 16 | 56 | 16 | 125 | 4 | 尖角 | Microkevlar D |

| C445 200 D 35 150 S D | 20 | 70 | 20 | 150 | 4 | 尖角 | Microkevlar D |

| C445SL SLOTTING | ||||||||||||

| ISO | SMG | ap | ae | vc | Zn = 4 | |||||||

| GROUP | x Dc | x Dc | (m / min) | 1.5 | 3 | 6 | 10 | 12 | 16 | 20 | ||

| P |

E 1 - 2 |

0.50 | 1.00 | 122 | n (rev/min) | 25890 | 12940 | 6470 | 3880 | 3240 | 2430 | 1940 |

| fz (mm) | 0.005 | 0.011 | 0.022 | 0.036 | 0.043 | 0.058 | 0.072 | |||||

| 104 - 140 | vf (mm/min) | 559 | 559 | 559 | 559 | 560 | 560 | 559 | ||||

|

E 3 - 4 |

0.40 | 1.00 | 61 | n (rev/min) | 12940 | 6470 | 3240 | 1940 | 1620 | 1210 | 970 | |

| fz (mm) | 0.003 | 0.007 | 0.013 | 0.022 | 0.027 | 0.036 | 0.045 | |||||

| 43 - 79 | vf (mm/min) | 174 | 174 | 174 | 174 | 174 | 173 | 174 | ||||

|

E 5 - 6 |

0.30 | 1.00 | 30 | n (rev/min) | 6370 | 3180 | 1590 | 950 | 800 | 600 | 480 | |

| fz (mm) | 0.003 | 0.006 | 0.012 | 0.019 | 0.023 | 0.031 | 0.038 | |||||

| 12 - 49 | vf (mm/min) | 73 | 73 | 73 | 73 | 74 | 74 | 74 | ||||

| M |

E 8 - 9 |

0.50 | 1.00 | 98 | n (rev/min) | 20800 | 10400 | 5200 | 3120 | 2600 | 1950 | 1560 |

| fz (mm) | 0.003 | 0.005 | 0.011 | 0.018 | 0.021 | 0.028 | 0.035 | |||||

| 88 - 107 | vf (mm/min) | 220 | 220 | 220 | 220 | 220 | 220 | 220 | ||||

|

E 10 - 11 |

0.40 | 1.00 | 76 | n (rev/min) | 16130 | 8060 | 4030 | 2420 | 2020 | 1510 | 1210 | |

| fz (mm) | 0.002 | 0.005 | 0.010 | 0.016 | 0.019 | 0.026 | 0.032 | |||||

| 67 - 85 | vf (mm/min) | 155 | 155 | 155 | 155 | 155 | 155 | 155 | ||||

| K |

E 12 - 13 |

0.50 | 1.00 | 82 | n (rev/min) | 17400 | 8700 | 4350 | 2610 | 2180 | 1630 | 1310 |

| fz (mm) | 0.007 | 0.014 | 0.028 | 0.046 | 0.056 | 0.074 | 0.093 | |||||

| 64 - 101 | vf (mm/min) | 484 | 484 | 484 | 484 | 486 | 484 | 486 | ||||

|

E 14 - 15 |

0.30 | 1.00 | 44 | n (rev/min) | 9340 | 4670 | 2330 | 1400 | 1170 | 880 | 700 | |

| fz (mm) | 0.004 | 0.008 | 0.016 | 0.027 | 0.033 | 0.044 | 0.054 | |||||

| 26 - 62 | vf (mm/min) | 152 | 152 | 152 | 152 | 153 | 153 | 152 | ||||

| S |

E 19 |

0.20 | 1.00 | 21 | n (rev/min) | 4460 | 2230 | 1110 | 670 | 560 | 420 | 330 |

| fz (mm) | 0.005 | 0.009 | 0.018 | 0.030 | 0.036 | 0.048 | 0.060 | |||||

| 12 - 30 | vf (mm/min) | 80 | 80 | 80 | 80 | 81 | 81 | 79 | ||||

|

E 20 |

0.20 | 1.00 | 21 | n (rev/min) | 4460 | 2230 | 1110 | 670 | 560 | 420 | 330 | |

| fz (mm) | 0.005 | 0.009 | 0.018 | 0.030 | 0.036 | 0.048 | 0.060 | |||||

| 12 - 30 | vf (mm/min) | 80 | 80 | 80 | 80 | 81 | 81 | 79 | ||||

|

E 21 |

0.20 | 1.00 | 21 | n (rev/min) | 4460 | 2230 | 1110 | 670 | 560 | 420 | 330 | |

| fz (mm) | 0.005 | 0.009 | 0.018 | 0.030 | 0.036 | 0.048 | 0.060 | |||||

| 12 - 30 | vf (mm/min) | 80 | 80 | 80 | 80 | 81 | 81 | 79 | ||||

|

E 22 |

0.20 | 1.00 | 34 | n (rev/min) | 7220 | 3610 | 1800 | 1080 | 900 | 680 | 540 | |

| fz (mm) | 0.004 | 0.008 | 0.017 | 0.028 | 0.034 | 0.045 | 0.056 | |||||

| 16 - 52 | vf (mm/min) | 121 | 121 | 121 | 121 | 121 | 122 | 121 | ||||

耐高酷乐刀具(西安)有限公司

耐高酷乐刀具(西安)有限公司